Seawater Flow-Through - the rising star in salmon investing

Flow-through seawater systems are having a moment - the are attracting the majority of investor attention for new projects and have posted some encouraging biological results. Here are a few examples:

From Salmon Evolution

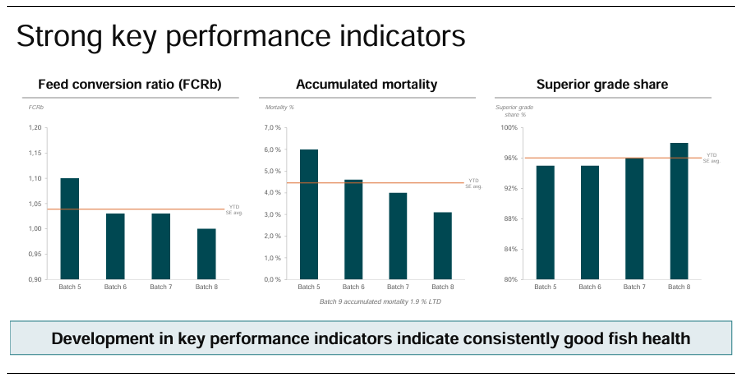

Snip from Salmon Evolution report

From Andfjord:

Snip from Andfjord Q2 2024 report

Bluegreen – Marine Donut project

Snip from recent media article

These are pretty encouraging results representing survival, quality and feed conversion results that net pen producers haven’t enjoyed in quite a while. if these results hold - that’s a huge “if” as we have nowhere near enough experience with these systems to claim that this what the future looks like - and nearshore net pens and RAS facilities continue to struggle with production challenges, pressures will grow to make these kinds of flow-through systems the norm for future development.

Freshwater versus seawater flow-through systems

Flow-through systems are not new – in fact, they are probably the oldest form of aquaculture facilities in operation. Historically, flow-through systems were almost exclusively freshwater farms – water was pumped from the ground or fed by gravity through a spring, stream of river. Recirculating aquaculture systems (RAS) were developed in response to the operational limits of freshwater flow-through farms. Key issues with these farms included:

1) Limitations on available water – in applications where water was pumped out of the ground, there could be measurable impacts on sensitive aquafers and, in many cases, significant competition for water with terrestrial farming irrigation requirements. Idaho trout farms, for example, are worth far more for the value of their water rights than they are for the profitability of their farming operations.

2) Challenges with water chemistry – in a hatchery I managed in the US, the water we used flowed through beds of crushed oyster shells to introduce more hardness. Without this step, we had significant issues with egg hardness and smoltification. We also had to put significant energy into stripping CO2 and adding oxygen to incoming ground water – in terms of water quality, not all water sources are created equal.

3) High energy costs – in situations where water was pumped from depth to supply the operation, electricity costs could be very high in the same hatchery mentioned above, the return-on-investment for constructing a RAS facility was largely driven by savings in electricity costs. In gravity-fed operations, this was not an issue.

4) Poor production results – in situations where the water was supplied by gravity rather than pumping from an aquafer, the volume of water available was often a concern and generally declined in quality and flow over time. Most of these systems were structured to have water pass through several production units before it was released from the facility. Fish in the ponds or raceways at the end of the line were generally subjected to the poorest environmental conditions and had the poorest results.

5) Limited biosecurity – if a farm was using an exposed surface water source – a stream or river for example, the presence of wild fish in the water source could spread disease to the farmed stock. These water sources were also vulnerable to negative events upstream of the farm – two examples come to mind – a dead cow in the water upstream of a hatchery contaminated the water for days until it was found and removed, in another, a landslide upriver from a tank farm impacted water quality until the mud and debris were washed away. Saprolegnia spores are present in many freshwater sources and would create fungal sores when scale or mucous layers were disrupted or on eggs and fry during early rearing.

Potential Advantages of seawater flow-through

In terms of the projects highlighted at the start of this blog, what makes these systems relatively novel in the scheme of history, is that they are saltwater flow-through. Key advantages include:

1) Unlimited water supply – even in cases where saltwater is pumped through saltwater boreholes, there is little or no risk that the volume of water available will diminish

2) Water chemistry – in most cases, water is drawn from depths below the photic layer where temperatures are stable and few of the organisms – plankton, sea lice, bacterial diseases – that create management problems in net pens are present.

3) Performance - while accepting that the data set is somewhat limited, they provide excellent biological performance. Given the almost unlimited availability of water, there is no need to repeatedly use water through several hatchery stages – this improves water quality and limits the wastewater treatment burden at the hatchery exit.

4) Energy costs – most modern flow-through projects are built on low shorelines and require very little lift to create flow in culture ponds. When I first heard about these projects, I had assumed they would require a great deal of energy to lift water from depth but as I now understand the hydraulic flows, water is lifted out of the culture tanks – a lift of only a few feet – and water is then drawn into the system via the inlet pipeline. In the marine donut example, most of the water is not lifted above the surface at all. They are not energy free like a gravity fed system, but energy consumption was a lot lower than I had assumed.

Simplicity

The image below is a snip from the Laxey investor presentation. This is a simplified layout but, compared to a RAS system, it is much simpler to build and operate. There is no biofilter, no denitrification system, no chiller etc. Similar to older freshwater flow-through systems, there is no need to manage water chemistry, a living biofilter or the anaerobic digestion of the denitrification system.

Snip from Laxey investor presentation

I had a very pleasant conversation with one of the legends in the RAS sector last week and he commented that the best RAS system in the world could easily malfunction if the operator didn’t know how to operate it. The unfortunate reality for most RAS operators is that the number of people globally who can reliably operate a RAS facility is extremely limited. Particularly on a full grow-out basis – most professionals with a depth of experience in RAS systems would have gained their experience on hatchery fish where there is a high tolerance for mortality and no concerns about off-flavours, harvest quality etc. The number of people with a depth of successful experience in full-grow-out RAS systems might number in the dozens.

A flow-through seawater system won’t be simple to operate but the expertise required for successful operation will lean toward “well trained operator” rather than “trained scientist” and should be easier to find.

Biosecurity

One potential weakness for these systems is the lack of filtration/disinfection on incoming water. While seawater drawn from depth is likely free of most of the pathogens and pests afflicting net pens, it is not sterile, and the potential exists for pathogens to find their way into the system. As with freshwater systems, not all seawater is created equal, and as more of these systems are built, we may find differences appearing. Adding a filtration and disinfection step on incoming water could, if I understand the hydraulic flows correctly, increase the complexity and energy requirements of the system significantly. A recent suggestion by Norwegian authorities that incoming water in seawater flow-through systems should be disinfected was met with horror by the industry.

Closing thoughts

I have gone to some lengths to flap my gums about why I don’t think these projects are a cost-effective, scalable option for meeting global food demand but, in the context of a high-priced salmon market that is chronically under-supplied, they are a good option for investing in a project with lower risks than RAS projects and fewer socio-political risks than net pen operations. Again, it is way too early to claim victory - a few encouraging results do not an industry make and the final cost structure will need proving.

Hopefully, investors have their eyes open to the potential the future may not be as rosy as the initial results may suggest. Given that the market capitalization for Salmon Evolution, a company that has harvested a total of less than 5,000 mt in the past two years, is currently standing at just under $300m US and has yet to deliver positive earnings per share, my optimism may be misplaced. Something to watch for sure,

Stock pricing Oslo Stock Exchange - February 5th, 2025

If you are still reading, I salute you. Feedback and comments welcomed - either below, via LinkedIn, or email at Info@AlanWCook.com